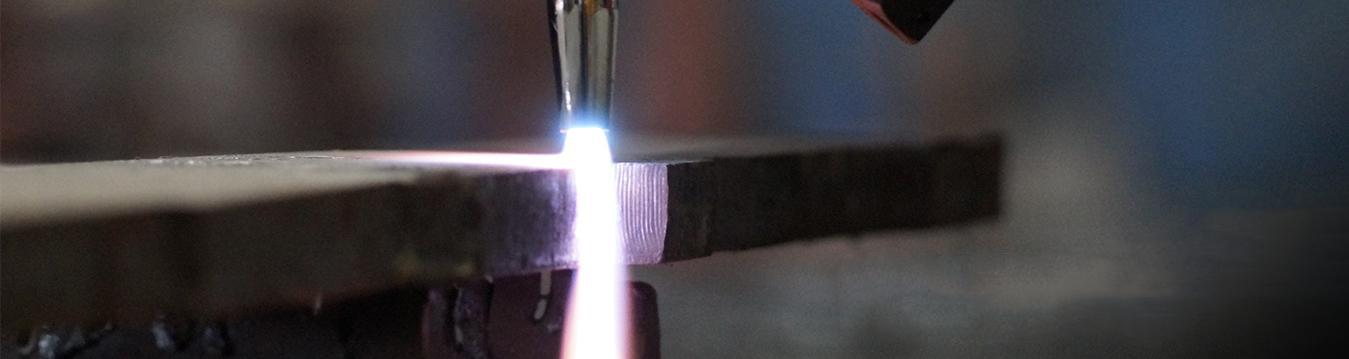

TotalEnergies is committed to offer more affordable, efficient and cleaner products to customers by innovating and improving constantly. TotalEnergies has launched TotalEnergies LPG Cutting Gas, an innovative new product for metal cutting and temperature intensive applications.

Acetylene is the most commonly used fuel gas in metal cutting applications, however, due to its high flammability range and difficulty in handling, alternatives are being pursued by the customers.

A high-performance and cost-effective solution for Metal Cutting by TotalEnergies

Designed for efficient Oxy-Fuel Cutting, TotalEnergies LPG Cutting Gas provides safer operability, high-cost savings, and excellent performance over acetylene and regular LPG. Its superior surface finish with high cutting speed makes it an excellent choice for fabricators, scrappers, and other metal-working industries.

Potential Applications of TotalEnergies LPG Cutting Gas

TotalEnergies LPG Cutting Gas is an additized LPG curated for metal cutting and other temperature intensive applications.

- Metal Cutting

- Heating

- Straightening

- Hardening

- Soldering

- Welding

- Brazing

- Coating

- Stress Relief

- Other industrial Heating Application

Package Size Available

Why use TotalEnergies LPG Cutting Gas?

- Superior surface finish

- High flame temperature

- High heat input

- Excellent cutting finish

- Safer than Oxy-Acetylene

- Non-toxic and safe to handle

- Industrially acceptable

Comparison of fuels

| Properties | LPG | Acetylene | TotalEnergies LPG Cutting Gas |

| Shock Sensitivity | Stable | Un-Stable | Stable |

| Explosive Limits in Air (%) | 1.9-9.1 | 2.5-80 | 1.9-9.1 |

| Max Allowable Pressure | 25 PSIG | 15 PSIG | 25 PSIG |

| Backfire Tendency | Low | High | Low |

| Toxicity | Low | Low | Low |

Heating Values of Fuel Gases

| Parameter | LPG | Acetylene | TotalEnergies LPG Cutting Gas |

| Neutral Flame Temp. ⁰C | 2593 | 3149 | 2982 |

| Volumetric Heat Release (Btu/ft3) | 2498 | 1470 | 2612 |

What makes TotalEnergies LPG Cutting Gas the customer’s choice?

- Higher cutting speed - increased productivity

- Improved Fuel Savings

- Faster Cutting Speed

- Lower oxygen consumption

Handling & Protection

Personal Protective Equipment (PPE) is mandatory in a metal cutting workshop as occupational safety is of utmost importance for this sector. Hazards exist in every workplace in many ways, and the best way to avoid them is by following recommendation of safety.

Employers must provide PPE to their employees and ensure its use.

PPE items such as gloves, footwear, protective goggles/face shield, hearing devices (earplugs or muffs), hard hats, and full bodysuits.